Usage and precautions of metal hoses

Column:FAQ

Time:2023-04-20

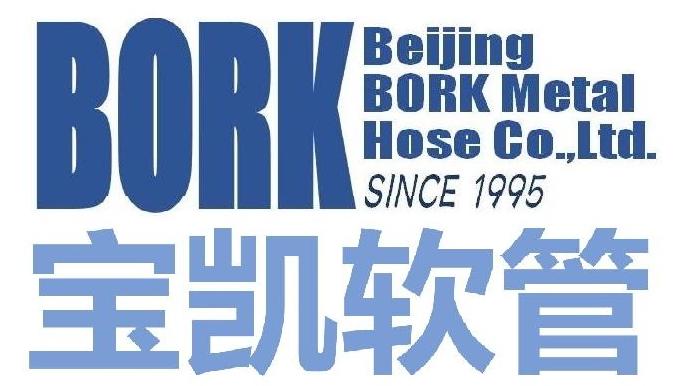

It is also called lateral movement or parallel eccentricity. Take the hose with flanges at both ends as an example. The two flanges keep the same distance and do Parallel transport.

Metal hoses in:

Offset Motion

Radial Motion

Axial Motion

Permanent Bend

Random Motion

Used in a certain movement in.

1 Eccentric motion

(Offset Motion)

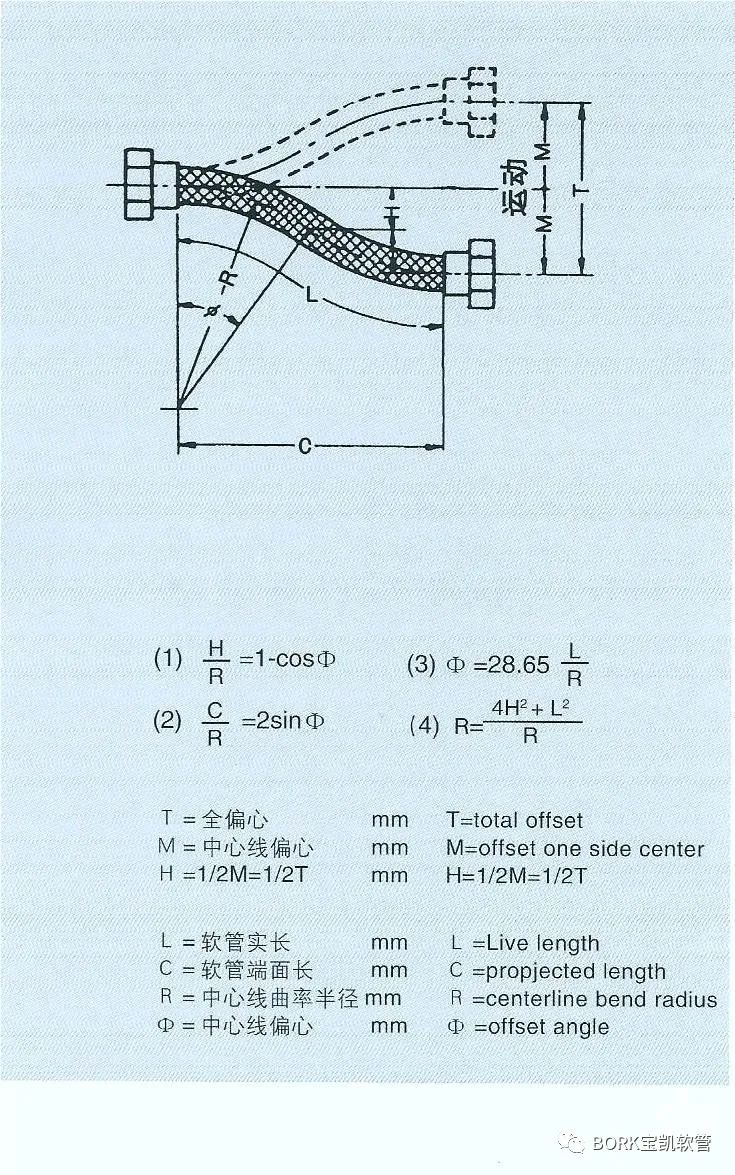

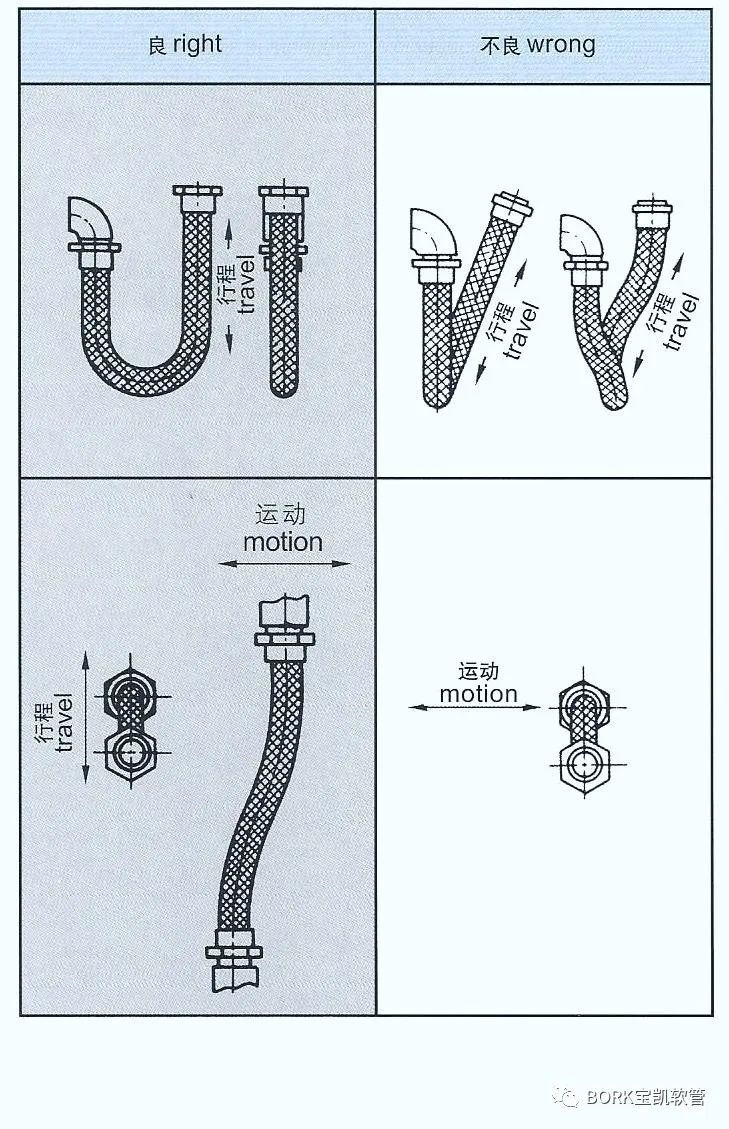

2 Radial movement

(Radial Motion)

Radial motion refers to the horizontal or vertical movement of the starting point of an arc when bending and assembling according to Figures A and B. It is generally referred to as a moving arc, and the amount of movement is represented by the horizontal or vertical movement distance. If the total movement T is known and the radius of curvature is chosen appropriately, the actual length L of the hose and the length K of the arc can be calculated according to the formula shown.

Total length=L+length of joint

3 Axial motion

(Axial Motion)

Axial motion refers to the displacement of a hose along the axis, expressed as the amount of expansion or contraction of the hose or the percentage of expansion or contraction relative to its original length. Hoses with mesh sleeves and S-shaped hoses are not suitable for this purpose. Seamless hoses without mesh sleeves can be used, but there are limitations at the sag point.

We recommend using expansion joints when absorbing axial displacement.

4 Permanent elbow

(Parmanent Bend)

5 Irregular movement

(Random Motion)

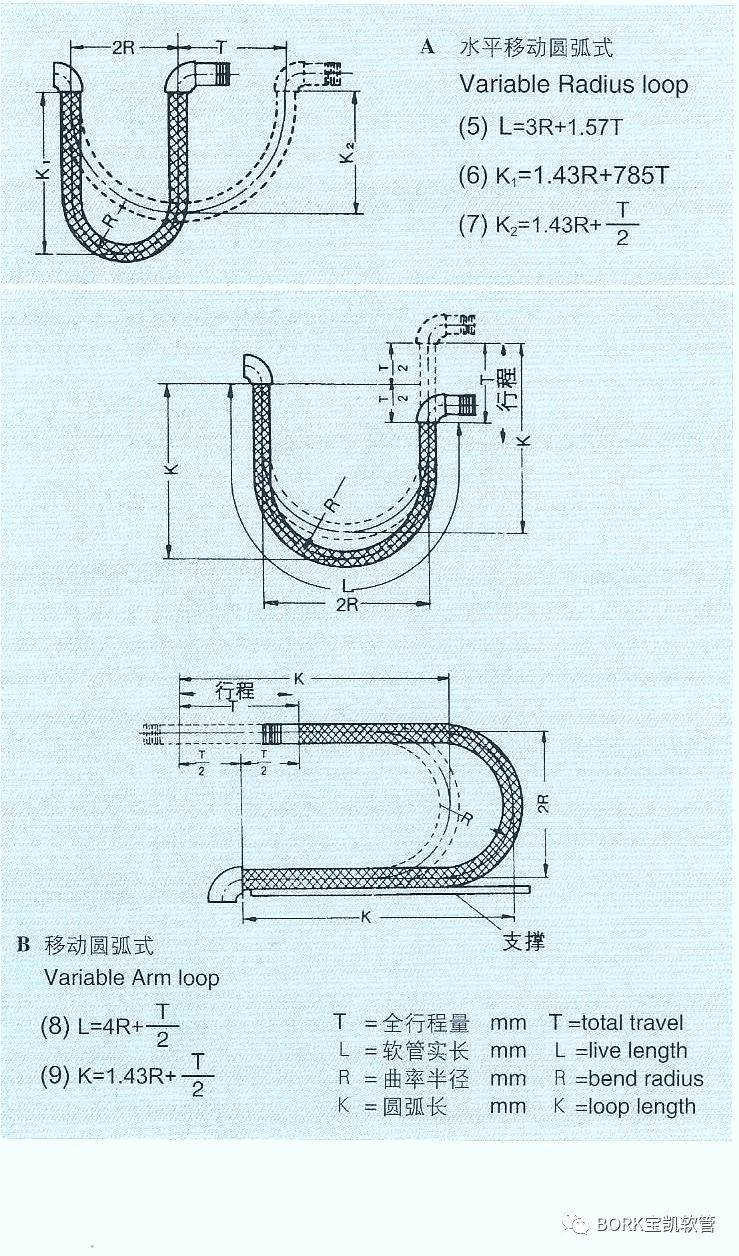

Precautions for assembly and use (Proper Installation)

Do not create distortion

(DO NOT TORQUE)

Twisting during assembly.

To reduce hose damage caused by twisting, it is recommended to use a loose flange or union at one end of the hose.

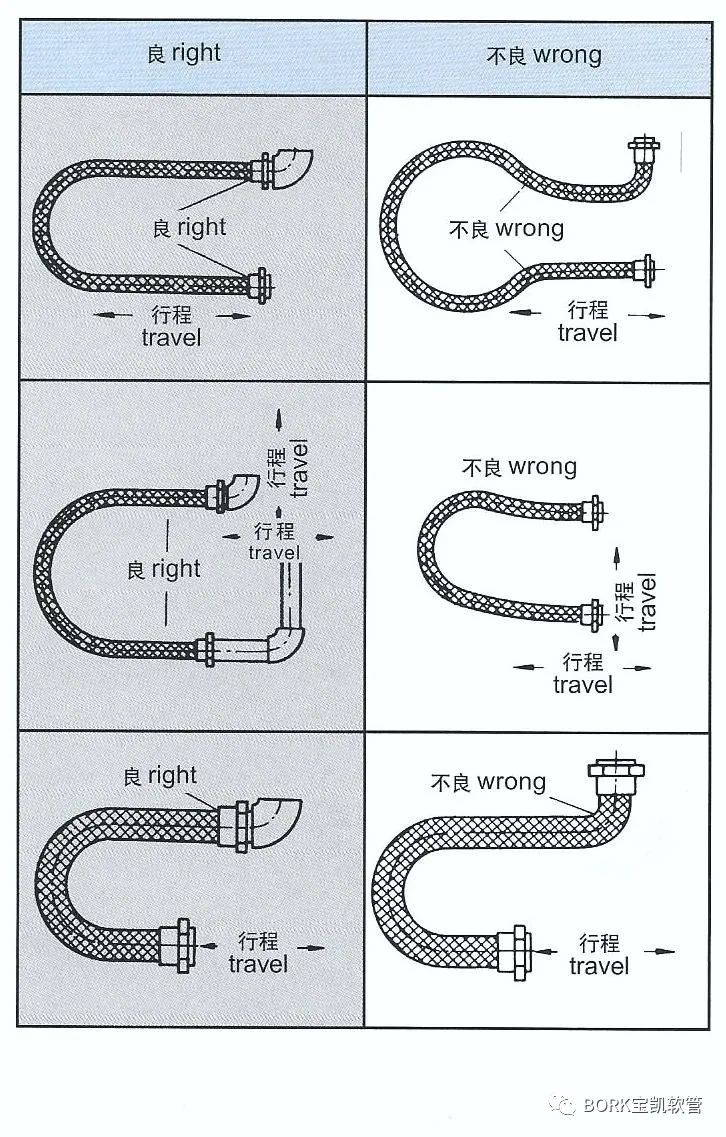

Sharp bending during assembly.

The hose inevitably bends during assembly, but it often bends sharply due to incorrect installation. The following figure shows three examples. When using hoses under conditions smaller than the minimum bending radius, fatigue is prone to occur, resulting in hose damage in a short period of time.

Avoid sharp twisting

(AVOID SHARP BEND)

Quality Management System Certification: ISO9001

Environmental Management System Certification: ISO14001

Previous:

What are the main uses of metal hoses